Engineering

Successful injection molds begin with impeccable engineering and Precision Molds houses a full-time design & engineering department with over 38 years of experience, ensuring a high quality product with economical & efficient tooling. We combine skills for building steel molds and aluminum molds.

Quality Assurance

We strive to provide our customers with the highest quality in injection molded plastic products & services. We have implemented a quality assurance system to plan, control, measure, and continuously improve our business & molds.

Rapid Prototyping

We provide an economical alternative to traditional stereo lithography prototyping. Our prototype capabilities builds ABS models, including internal features directly from CAD/STL file. Your prototype is a high quality, 3D part that can be painted/glued as necessary and are functional/ready to use immediately, ensuring an accurate production result.

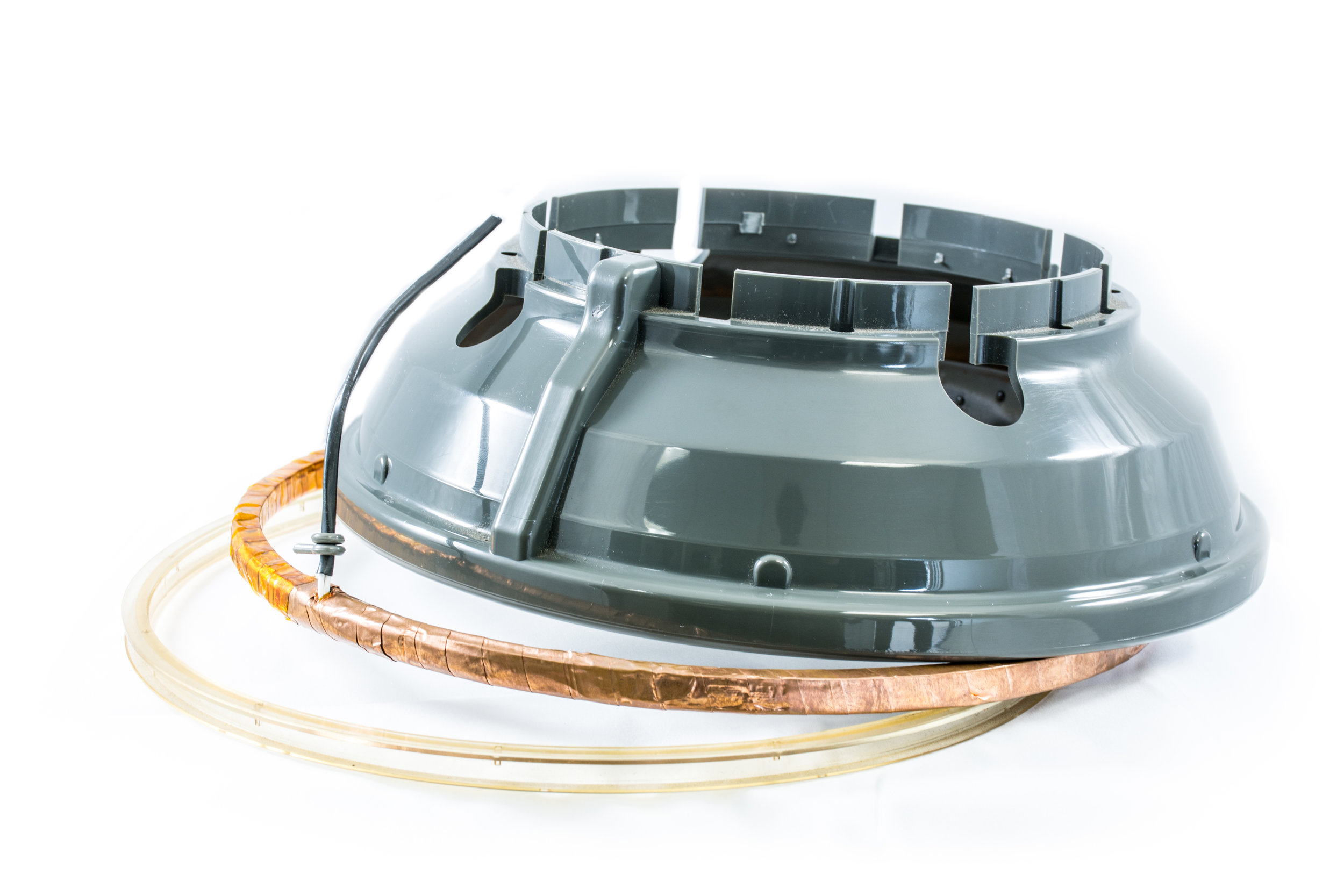

Metal / Plastic Conversion

Different kinds of gears made of Acetal material, some straight gears and some spiral gears.

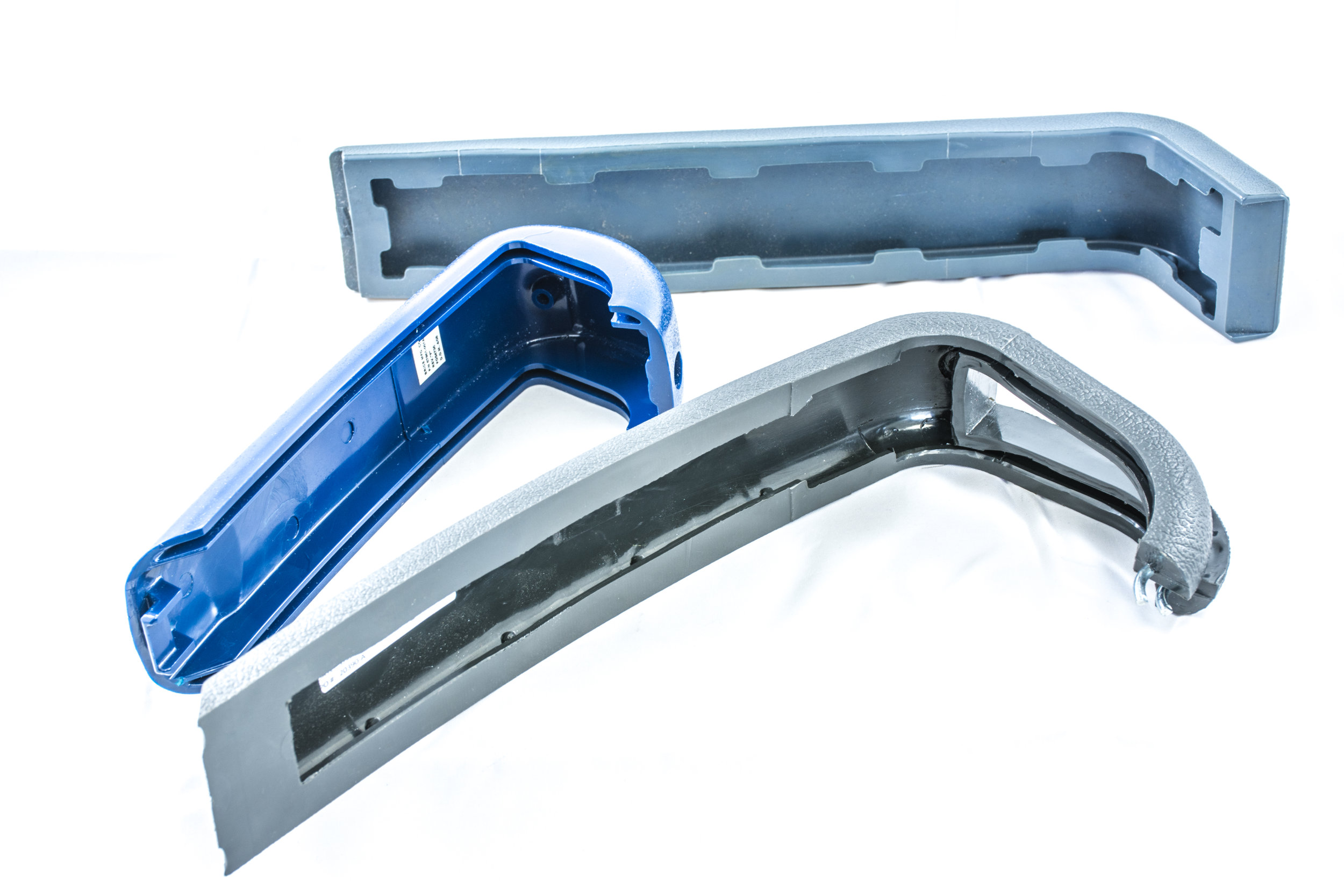

Industry Contracts

We specialize in, but is not limited to moldings for the following industries:

Aerospace, Automotive, Commercial Aircraft, Computer, Cosmetics, Electronics, Medical & Dental, Military, Contracting, Pool & Spa